Verhoff Machining & Welding, Inc. is a family owned operation employing 120 dedicated staff. Located in Continental, Ohio, Verhoff services the agriculture industry, industrial manufacturing, heavy equipment and military industries. The company experienced a significant reduction in sales to the defense supply chain, and needed core strengthening of the manufacturing operations and decided that implementing lean manufacturing would benefit them the most.

Implementing lean manufacturing, also known as continuous improvement, helps to restructure workflow which saves time and money, allowing manufacturers to reduce their wasted time and effort.

The company reached out to CIFT, a regional Ohio Manufacturing Partnership (MEP) partner to implement the lean program. The assistance of CIFT/Ohio MEP proved to be critical to the program’s success.

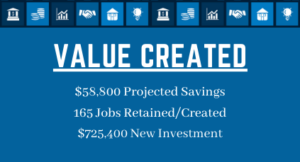

To help Verhoff with their key areas of improvement, CIFT provided the “on-site” process education and “hands-on” shop floor experience and implementation of lean principles and techniques. The program’s implementation of lean manufacturing is projected to result in 165 jobs retained or created, and a potential revenue of more than $13,000,000 on an annual basis.

The cost savings from incorporating the lean program is estimated to be more than $58,800.

In addition to increased sales and jobs, Verhoff was able to purchase $725,400 worth of new investments.

“The program was a much needed resource to help elevate our company to meet the needs of the workload,” said Barb Rieman, accounting and human resources, Verhoff

This project was funded in part by the U.S. Department of Defense Office of Economic Adjustment through a grant managed by The Ohio State University. To learn more how Ohio MEP and implementing lean manufacturing can help your company, please contact us through our website.