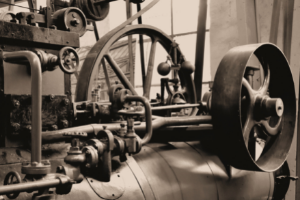

Are You Stuck In The Past? The manufacturing industry has seen an immense amount of change throughout history. Technology has…

2021 May

Connect with Isabel Montez on LinkedIn. We believe it’s important to know who you’re working with. We’re continuing our Getting…