I had the privilege to speak at the Food Safety Tech’s Hazards Conference Series that was held at The Ohio State University in partnership with OSU’s Center for Foodborne Illness Research and Prevention (CFI). The two-day event offered practical education on the detection, mitigation, control, and regulation of food hazards, from presentations led by academia and industry professionals.

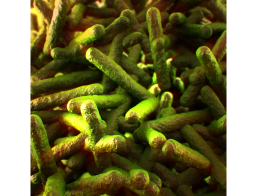

I lead a session on Mitigating Listeria Risks and Responding to Contamination in high-risk food items such as ready-to-eat meats and ice cream. Over the past few decades, we have seen several large recalls due to product contamination from Listeria Monocytogenes. According to the CDC, Listeria is the third leading cause of death from foodborne illness in the United States as an estimated 1,600 people get sick from Listeria each year, and about 260 die.

To prepare, I spent some time talking with several organizations that have experienced recalls due to potential Listeria adulteration to gather information on lessons learned and what they wished they would have known. In talking with these organizations, much of the information shared overlapped with what they are doing to prevent future Listeria contamination issues and the lessons their organization learned post-recall.

In short, over the past few decades, the food industry has advanced and innovated on how to mitigate Listeria and other pathogen contamination through; new regulatory requirements and guidance documents for industry, improvement, and innovations in processing procedures and formulation, enhancing sanitation programs, improving and monitoring equipment sanitary design and implementing environmental monitoring programs.

Even with recent innovations and enhanced knowledge, shortcomings occur as we know Listeria is found everywhere in nature and unfortunately, deviations in programs occur and recalls may result. Here are the top 5 lessons learned from the organizations I spoke with that experienced recalls due to Listeria.

- Inadequate training/knowledge at all levels within the organization.

Often the individual responsible for implementing and maintaining the Food Safety Programs does an excellent job in ensuring daily tasks, checks, and documents are completed and is not the one who initially developed the food safety plan(s) and programs. With workforce challenges, not all individuals responsible for food safety have a strong microbiology background and aren’t fully knowledgeable in pathogen behavior. It’s ok if they are not a microbiologist but then do they have expert resources they can call upon and are they encouraged to utilize those experts when a positive finding or deviation in the food safety programs occurs so your organization can ensure a proper and effective root cause analysis is completed for issues.

In the same respect, all employees must understand the organism and gain the same sense of personal responsibility exhibited by the organization’s management team and regulatory officials. Often line workers are given the bare minimum training to check the box for regulatory or third-party audit certification requirements. All employees truly need to understand the severity of foodborne pathogens and why the company policies and procedures in place are so crucial to consumer safety as well as brand reputation.

- Failure to do or effectively conduct a root cause analysis for each positive finding.

Often a company’s environmental monitoring program has predetermined corrective action steps to take when a positive hit is found during routine swabbing. Usually, it consists of re-swabbing until so many consecutive negative results are received. When conducting the root cause analysis, the contributing factor(s), or what went wrong, is usually the only thing identified. A true root cause to find out why it went wrong is being missed. If your organization is only addressing the contributing factors without addressing the underlying reasons why the contributing factors were present, can result in a repetitive cycle of short-term corrections followed by gradual loss of food safety controls, resulting in recurring problems. Does your organization have a knowledgeable team to conduct proper root-cause analyses?

- Not truly knowing employee traffic flow and habits.

When was the last time the traffic flow at your facility has been evaluated? Have you looked beyond product flow and evaluated employee movement across the entire facility including within GMP areas and between GMP and non-GMP areas? What about maintenance workers, material flow, forklift traffic, and pallet jack movement? Are handwashing, GMPs, PPE and product handling procedures being followed properly? Many times mundane tasks get overlooked from being evaluated. Adjustments to employee practices and traffic flow can be the most cost-effective change to make as no capital investment is needed and can greatly reduce your risks from cross-contamination if implemented and properly maintained.

- Having facility and equipment design flaws.

All equipment from new to old and facility integrity such as walls, floors, drains and ceiling need to be evaluated continuously. Do your facility floors have cracks or separation? How is the wall-to-floor junctions? If your equipment isn’t bolted to the floor, how often is it moved to ensure proper cleaning occurs at the floor-to-leg junctions? Equipment and facility design plays a vital role in how well your sanitation team can properly clean and sanitize. Every place there are exposed threads, hollow pipes, poor welds, hard-to-reach areas and water/product accumulation points increases your risk for pathogen harborage areas.

Whether new or old, your facility equipment should be evaluated to the 10 Principles of Food Safety Design. When new equipment is being considered, a cross-functional team from operations, maintenance, engineering and food safety should be involved in the discussions. If deviations in equipment and/or facility are observed, then proper corrections need to be made in a timely manner.

- Not reassessing programs when findings occur or other changes happen.

All aspects of your food safety program need to be reassessed when something changes, such as new equipment or a change in process, or when a positive Listeria or other pathogen find occurs. When new equipment is purchased is your food safety plan, sanitation program, environmental monitoring program, list of swabbing sites, and other relevant programs being reassessed? What may be viewed as minor changes could lead to a significant increase in risk so no matter the change or deviation, all programs associated must be reassessed. The reassessment and reasoning behind the decisions made must also be documented.

Many of these same items were brought up and discussed among other speakers during the two-day event as they are very common challenges in food manufacturing. The goal of all food manufacturers must be to produce safe, wholesome food for the consumer. What is your organization doing to mitigate pathogen and other hazardous risks?