JTM’s commitment to excellence in food production, along with our experience and dedication to training, allowed us to address industry challenges head-on.

food safety

It has been nearly 8 years since the FSMA was finalized, and organizations of all sizes have been required to be in full compliance.

I had the privilege to speak at the Food Safety Tech’s Hazards Conference Series that was held at The Ohio…

Sutas and Nucharee Pipatjarasgit, immigrants from Bangkok, Thailand, came to the United States in 1968 with only $300 to pursue…

As workforce challenges continue across all sectors of manufacturing, attention to food safety and quality standards cannot take a backseat….

A properly planned, executed and maintained food sanitation program is vital to the success of any operation. So why can sanitation be such a challenge for many organizations? The challenges often occur because of three main reasons.

Connect with Stacy Vernon on LinkedIn. We believe it’s important to know who you’re working with. That’s why we are…

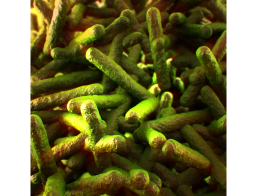

A facility producing ready-to-eat (RTE) product that is open and exposed to the environment post lethality, are to consider conducting environmental monitoring in their facility. So what is environmental monitoring and what does it mean to your facility?

The Leaf and Seed Café, a made-from-scratch vegan meal service that focuses on creating vegan meals that are reminiscent of childhood favorites, first started out in 2017 with just the idea of providing vegan meals for special events.

Amish Wedding Foods, operating in the center of Holmes County in beautiful Millersburg, Ohio, produces a wide variety of products…